AMCL MACHINERY LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AMCL MACHINERY LTD.

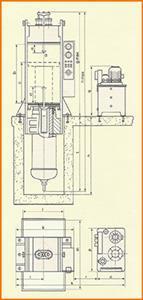

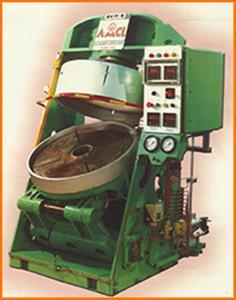

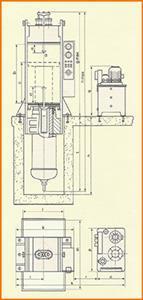

Bladder Curing Presses

Operation

The HB type presses have been designed especially for manufacturing and curing the bladders used in the AUBO, BOM and AUTOFORM presses.

The control of the Hydraulic system included in the equipment is designed such that the lower mould half carrying the uncured rubber approaches the upper mould half with high velocity during the first closing stage. Thereby, the total closing period is reduced to a minimum.

In the beginning of the pressing operation the closing speed is slackened automatically in order to obtain slow and uniform compression of the uncured material. After lapse of the curing time, the press opens automatically and the bladders for AUBO and BOM presses are removed from the lower core plate. The bladder for AUTOFORM presses is detached by means of a pneumatic device which can be included in the delivery package on specific order.

The two external mould portions and the core are cured by a direct steam connection.

The press along with the hydraulic power unit is delivered in a "ready for connection" condition, excluding curing platens. The timer/plc for automatic press opening after completion of the curing period as well as the steam / condensate piping are normal features of supply.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.